Tooling Manufacture

Fast, precise moulds for all SP Group technologies

What this solution offers

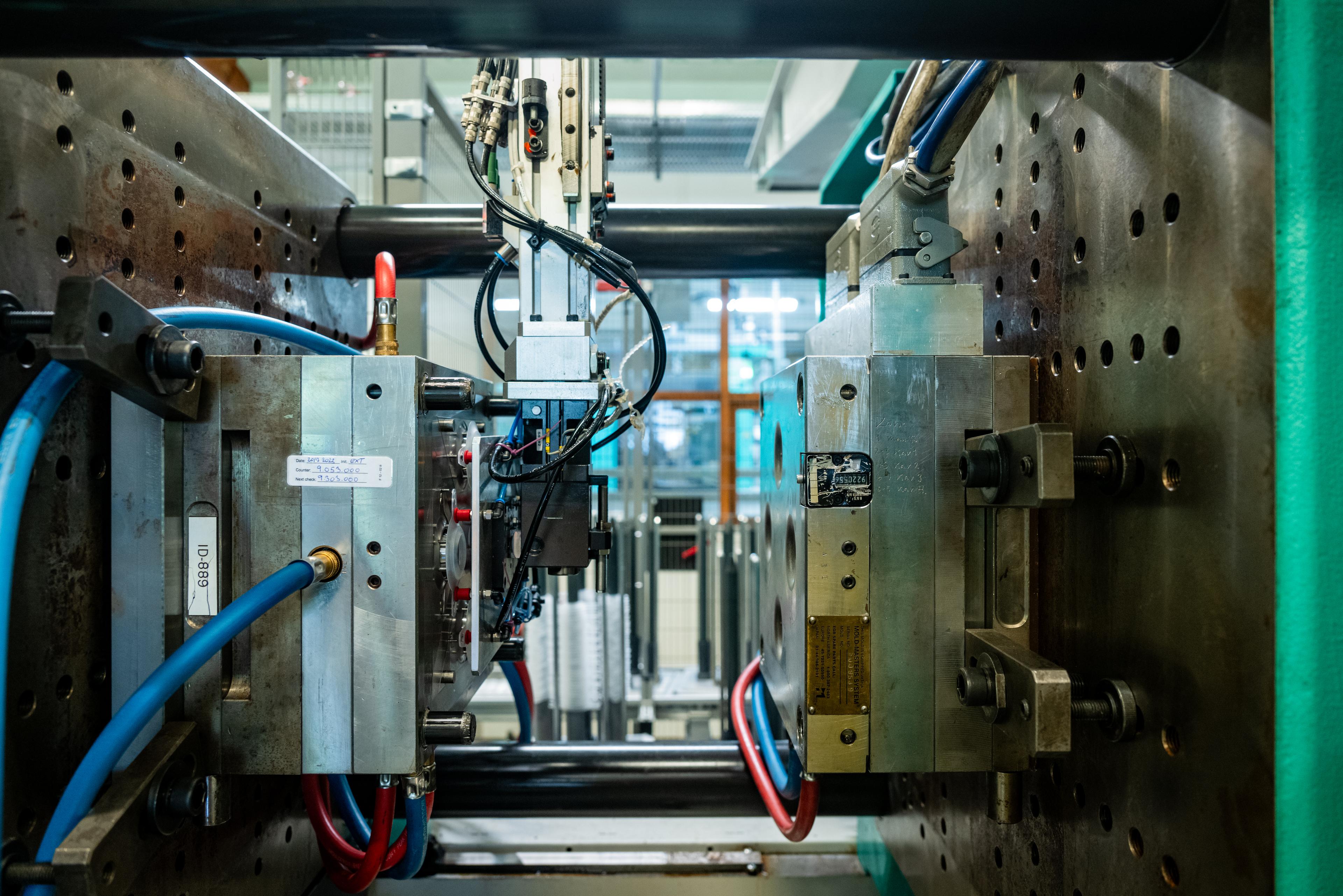

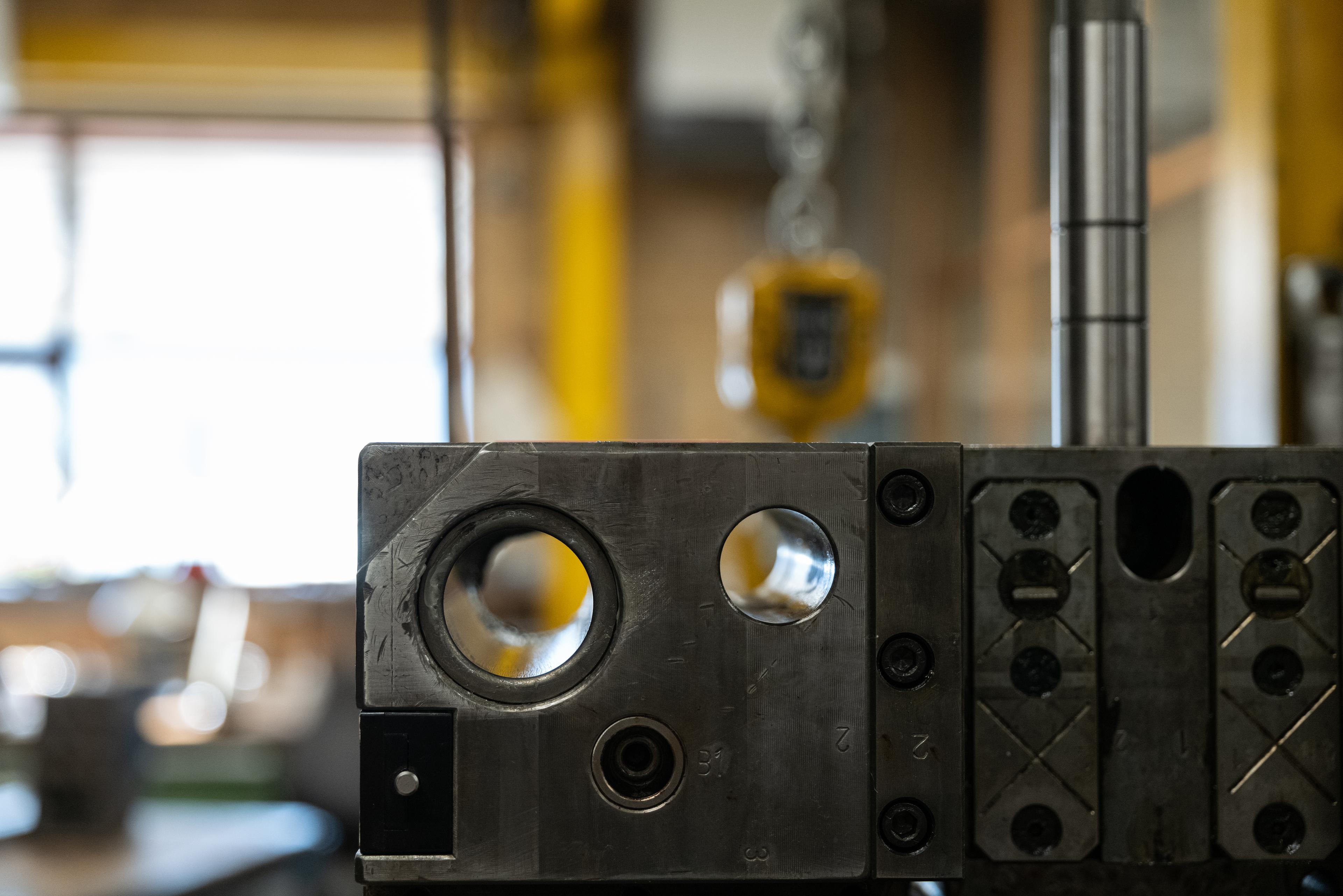

SP Group designs, mills and qualifies extrusion dies, thermoforming tools, RIM moulds and steel injection moulds in-house or with trusted partners.

Integrated try-out presses and CMM measurement ensure cavity accuracy within ±0.02 mm.

For injection moulds we manage hot-runner design, mould-flow optimisation and steel hardness up to 54 HRC. All files are safely stored for future ECO updates.

Key Benefits

- Single point of contact: Tooling and production under one roof.

- Accelerated lead-time: Tools in <4 weeks.

- Process-matched design: Extrusion, RIM, thermoform or injection.

- Digital validation: CMM reports and sampling videos supplied.

- Long-term support: Refurbish and modify tools as volumes evolve.