Composite Manufacturing

Glass- and carbon-fibre parts via vacuum infusion, RTM, prepreg & hand lay-up

What this solution offers

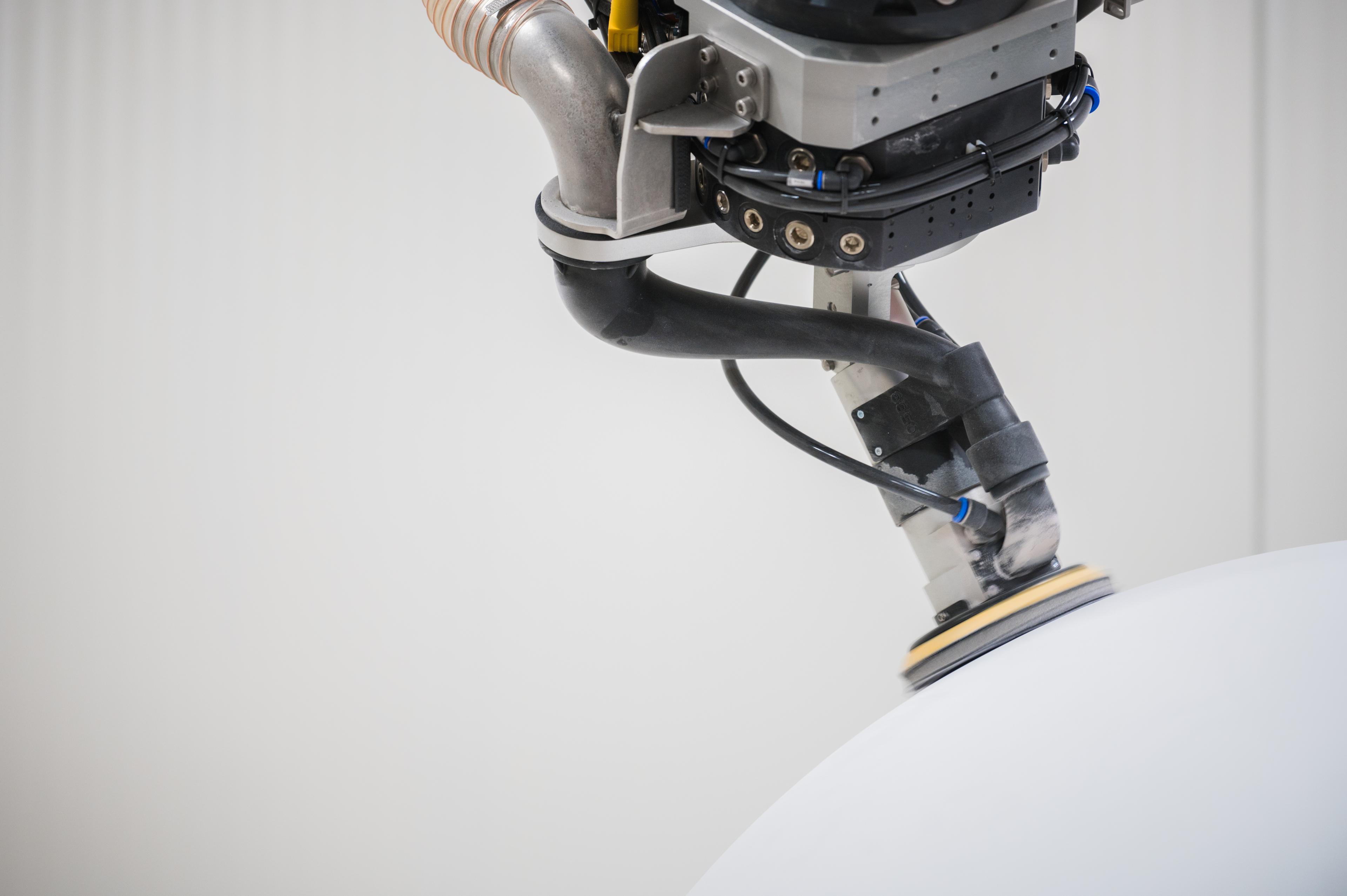

MM Composite, Bröderna Bourghardt and other SP Group units deliver structural composites for wind energy, transportation and defence. Using vacuum infusion and RTM, we produce high-fiber-volume laminates with Class A surfaces. Automated cutting tables and multi-axis machines precisely cut dry fibre, foam and prepregs, and multi-axis robots are used for post-processing operations such as trimming, drilling and milling — reducing variability and cycle time.

For ultra-large structures or low-volume series, certified laminators perform manual hand lay-ups under rigorous process control. Low-density cores — for example from in-house PUR production — can be integrated for sandwich designs, lowering weight by up to 45% without compromising stiffness. NDT ultrasound and 3-D laser scanning verify geometry and bond integrity before shipment.

Key Benefits

- High strength-to-weight: Up to 70 % lighter than steel.

- Process flexibility: Choose infusion for volume, hand lay-up for complex shapes.

- Integrated core options: Foam, honeycomb or PUR for stiffness.

- Corrosion & fatigue resistance: Ideal for offshore and automotive.

- Certified quality: ISO 9001, EN 9100 and customer-specific standards.