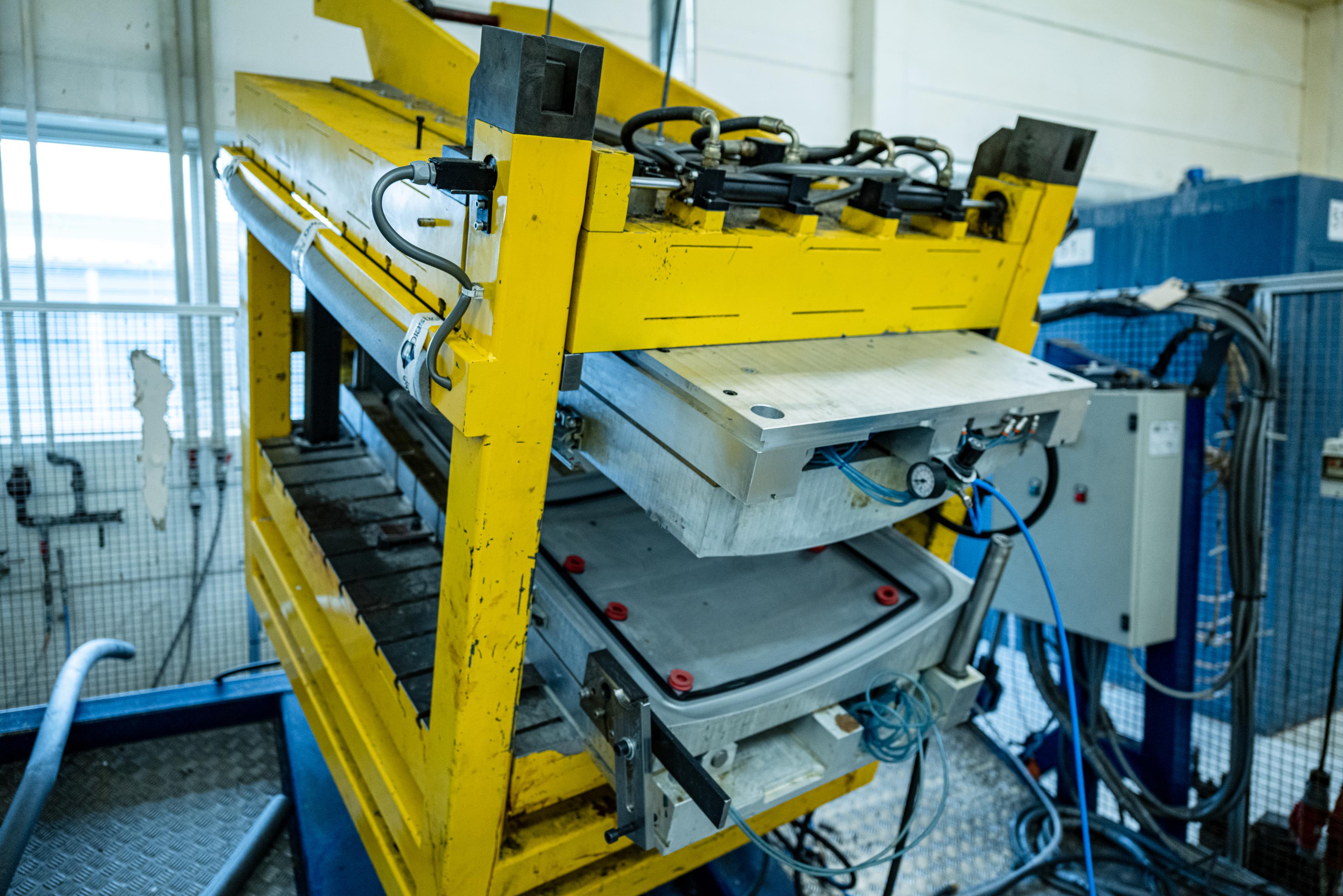

Reaction Injection Moulding

From small to large and lightweight to heavy parts in polyurethane (PUR) or DCPD (Telene®) for demanding applications

What this solution offers

RIM blends two low-viscosity components that react inside a temperature-controlled mould, expanding to fill even the most complex cavities. We process rigid, flexible and micro-cellular polyurethane (PUR) as well as DCPD (Telene®) for extreme impact performance . Typical parts range from electronic housings to agricultural body panels up to 3 m, with wall thicknesses from 3 mm to 25 mm. Tooling is aluminium or epoxy, priced a fraction of steel dies and ideal for batches from 100 to 20,000 a year. Integrated inserts, ribs and local foaming zones reduce secondary assembly.

Key Benefits

- Lightweight strength: Density from 35 g/l to 1.100 g/l. yet highly rigid

- Highest insulation performance: Down to 0,022 W/mK

- Low residual stress: Minimal shrinkage ensures dimensional stability

- Large formats possible: Mould envelopes over 3 m without warpage

- Multi-material flexibility: Choose solid PUR, foam or DCPD to match performance needs

- Economical tooling: Rapid aluminium moulds accelerate market entry