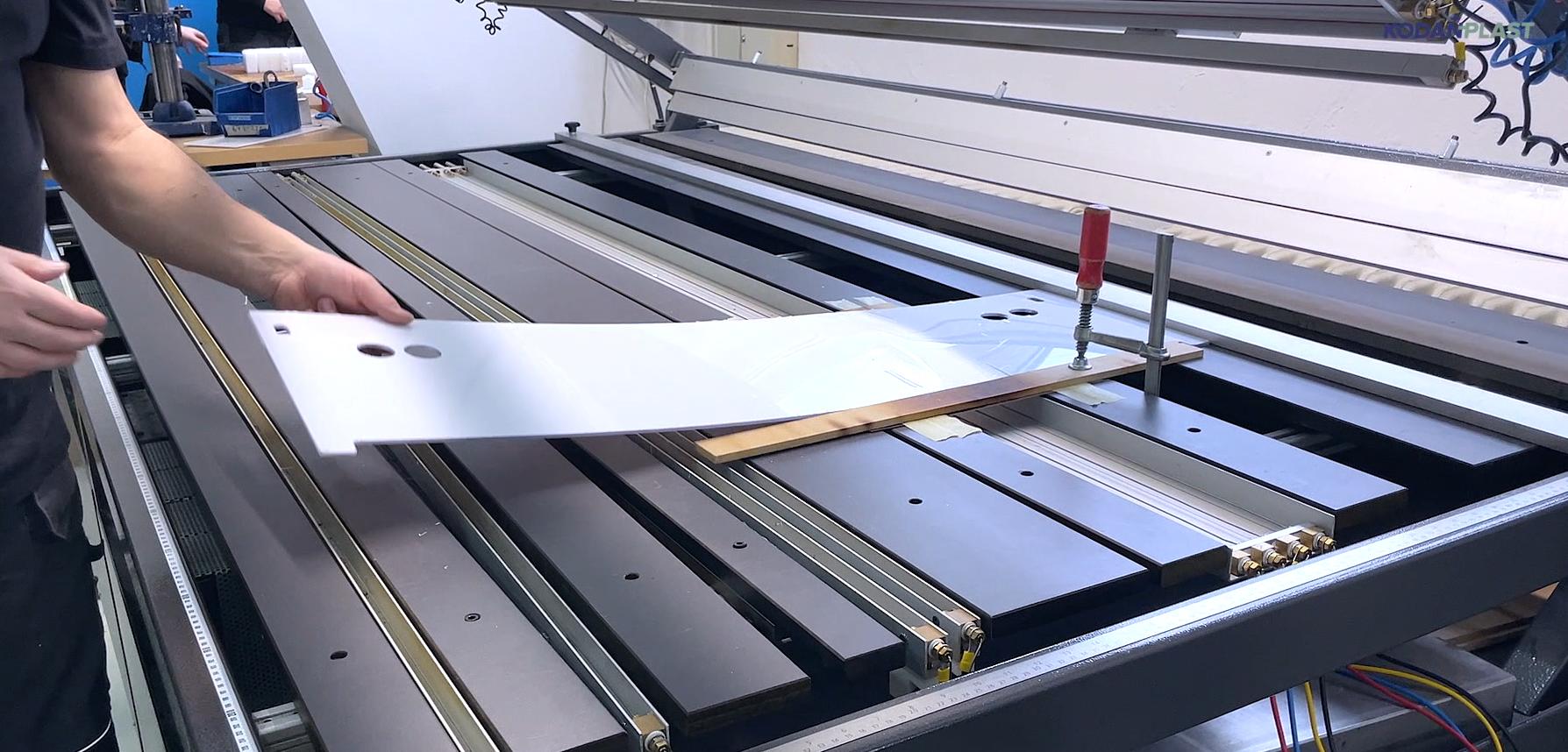

Precision Plastic Machining

CNC-milled and-turned parts for prototypes until series production of components

What this solution offers

Our dedicated companies in Slovakia and Denmark CNC machining & welding with all forms of plastic.

Five-axis simultaneous milling, live-tool lathes and automated pallet systems keep cycle times short and repeatability high.

Cooperation with SP Group’s designers allows fast feedback on manufacturability, while post-processing services such as bending, solvent welding, gluing, printing and laser engraving deliver a ready-to-install component.

Because we start from plates and rods, lead-times are counted in days, and design changes are handled by simply updating the CAM program.

Key Benefits

- Ultra-tight tolerances: Perfect for medical fixtures, conveyer system, test rigs etc

- No tooling investment: Economic for one-offs up to a few thousand pieces

- Sheet and rod material portfolio: Choose high-temperature, chemical-resistant or ESD-safe grades

- “One stop shopping” Marking, polishing and sub-assembly in one place

- Seamless scale-up: Migrate to moulding when volume grows, using the same SP Group team